CNC Machining

CNC machining technologies speed up the manufacturing process through repeatability. Once our experts enter and test the data for your design, we can replicate it quickly and accurately, time after time – ensuring precision and reducing production costs.

CNC Machining Equipment List

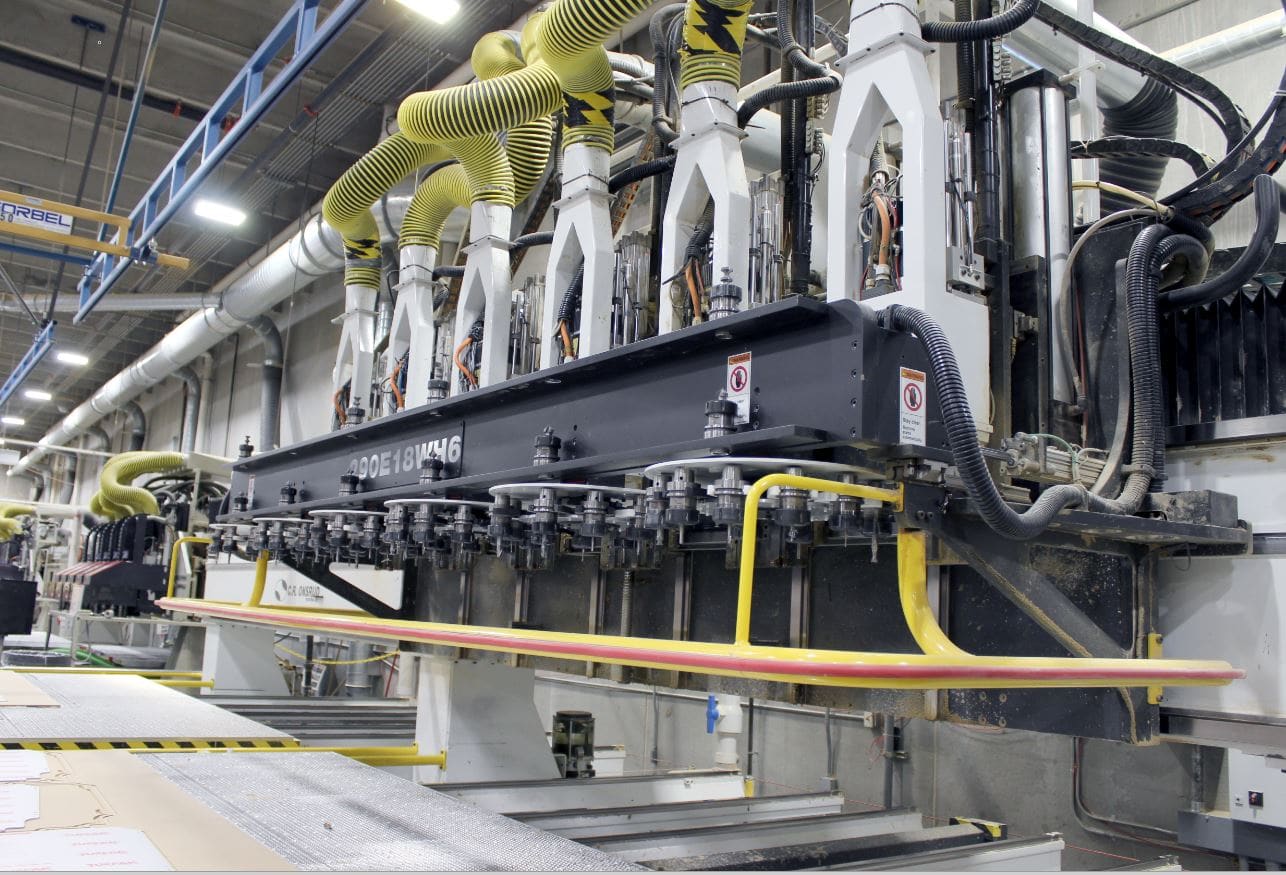

- Onsrud CNC Six-Head Router

- 98”x149”; twin table; 12 tool changers; used for large production runs

- Komo CNC Five-Head Router

- 85”x130”; twin table; 12 tool changers; used for large production runs

- Komo CNC Five-Head Router

- 85”x120”; twin table; 12 tool changers; used for large production runs

- Komo CNC Four-Head Router

- 85”x102”; twin table; 12 tool changers; used for large production runs

- Komo CNC Two-Head Router

- 5’x8’; single table; 8 tool changers; used for prototyping and small quantity runs

- Komo CNC Single-Head Router

- 5’x8’; single table; 8 tool changers; used for prototyping and small quantity runs

- DMS 5-Axis Routers

- 60’ by 72’ twin table

- 12 tool changers

- Schelling CNC Saw

- Up to 3″ of material can be stacked and cut at the same time; large platform tables handle full sheets with ease – up to 11′ by 12′

- Bridgeport

- CNC operated; capable of intricate machining operations; extendable ram allows for tilting the head to various angles

- CNC Edge Polishing Machine

- Inline finishing of materials up to 4 ¾” thick; variable edging to include polished, frost, diamond, satin, beveled and more