Forming

Precise, Highly Specialized Thermoforming Techniques

Customers across the country seek out Aubright for our uncommon thermoforming capabilities.

Small or large format, in low or high volume, we deliver with the speed and repeatable precision you need. We build all molds in-house, which saves time, ensures accuracy and allows quicker project turnaround.

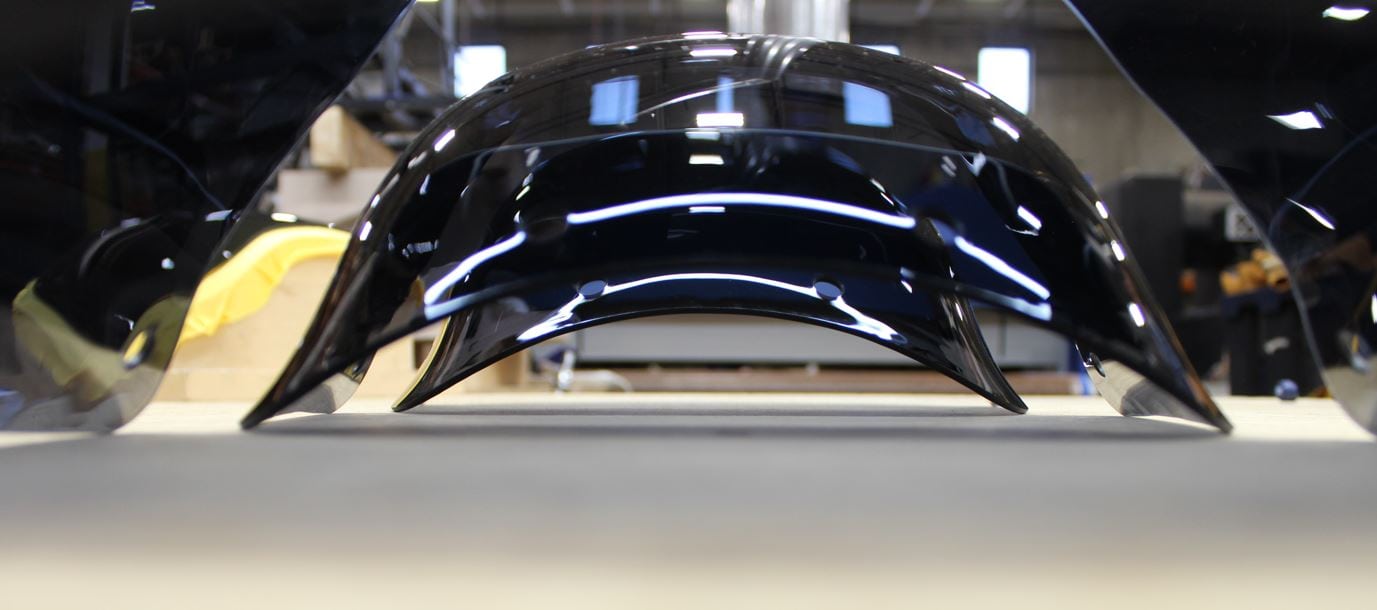

Drape Forming

For a variety of products that require a gradual curve or bend, Aubright offers almost three decades of quality, accuracy and consistency in drape forming (or oven forming) for exacting needs – including large parts at high throughput. Market applications include windshields for recreational vehicles, shields or guards for machine equipment.

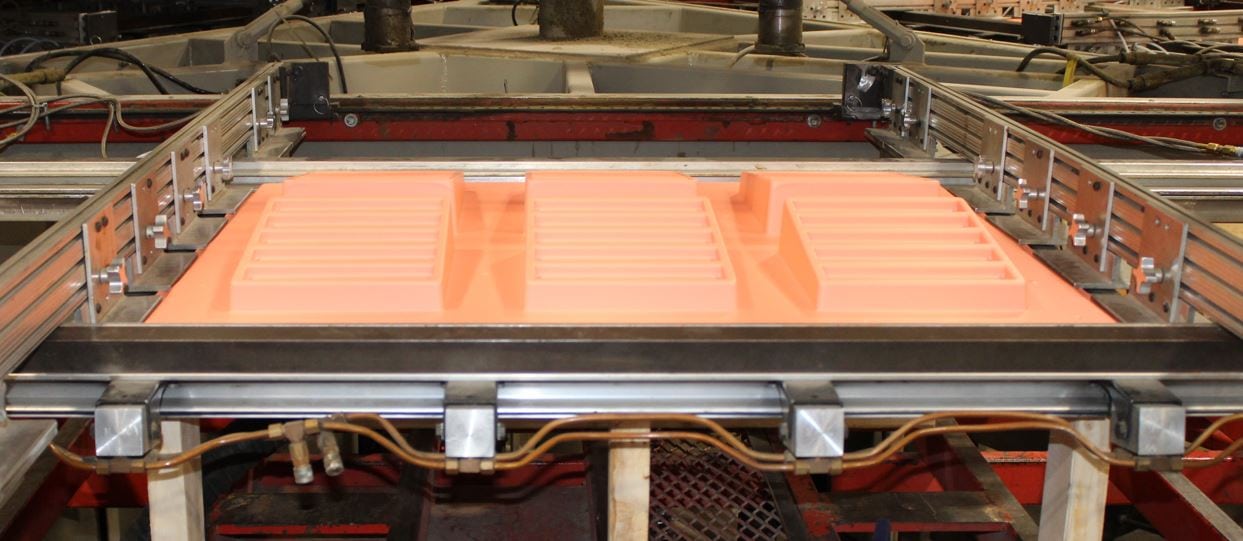

Vacuum Forming

For complex and elaborate plastic shapes and detailed plastic parts that require precise inside dimensions with deep draw, Aubright offers both small and large capacity vacuum forming capability. Hundreds of different applications include bakery trays, trailer tubs, truck bed liners, UTV/ATV roofs, gas tank shields and storage bins.

Aubright Forming Equipment

- Single Stage Forming Oven

- 50”x100” maximum sheet (ideal is 48”x96” or smaller); prototyping and small runs

- 50”x100” maximum sheet (ideal is 48”x96” or smaller); prototyping and small runs

- Wide-Belt Forming Tunnel Ovens (3)

- 60” wide by any length maximum sheet size; large runs

- Monark S-Series Single-Station Small-Format Vacuum Former

- 48”x72” maximum sheet size; prototyping and small runs

- MAAC Comet Three-Station Rotary Vacuum Former (2)

- 60”x96” maximum sheet size; large runs

- Cincinnati Press Brake (2)

- 10’ width; 135-ton capacity; used for effective bending of plastic