Plastic Fabrication Products For The OEM Industry

Regardless of the production challenges you face, Aubright is here to help you find the most cost-effective, efficient OEM solution. Our precision plastic production capabilities, engineering expertise, and “just in time” fulfillment allow us to serve as a knowledgeable partner in our customers’ success. To meet OEM industry needs, we fabricate parts to meet your specific tolerances and that fit within your existing manufacturing processes. We strive to deliver finished parts exactly when you need them.

Capabilities We Offer to the OEM Industry

We offer numerous capabilities for customers in the OEM industry, including:

- 3-Axis & 5-Axis CNC Routing. For projects with high-throughput demands, we offer a range of CNC cutting and routing solutions. A major benefit of these services is increased repeatability, which helps to accelerate the manufacturing process. We can replicate designs with optimal speeds and accuracy to ensure precision while reducing production costs.

- Screen Printing. Distinctive branding gives your business or product a unique identity, image, or personality. To help customers achieve this, we offer screen printing services to print custom images effectively and efficiently.

- Press Brake. With our 135-ton capacity, we can effectively bend plastic materials to meet our customers’ needs.

- Engineering. Our team of expert engineers can work with your design concept to successfully complete your fabrication project. In the process, we employ a combination of the best equipment, tools, configurations, fulfillment services, and other capabilities.

- Drape Forming. If our customers’ products require gradual bends or curves, we bring nearly three decades of accuracy, consistency, and quality to each drape forming or oven forming solution to meet our customers’ needs, including large parts with high throughputs. Some specific applications for drape forming include shields and guards for machine equipment along with recreational vehicle windshields.

- Vacuum Forming. If you need complex plastic parts and shapes with more elaborate details, we offer precise vacuum forming to meet these parts’ strict dimensional requirements. Our capabilities include small- to large-capacity vacuum forming. This process has many potential applications ranging from trailer tubs and truck bed liners to gas tank shields, ATV/UTV roofs, and storage bins.

Aubright supplies a diverse range of OEM products, including:

- Lighting Components/Diffusers: We provide a selection of lighting diffusers of various sizes and shapes.

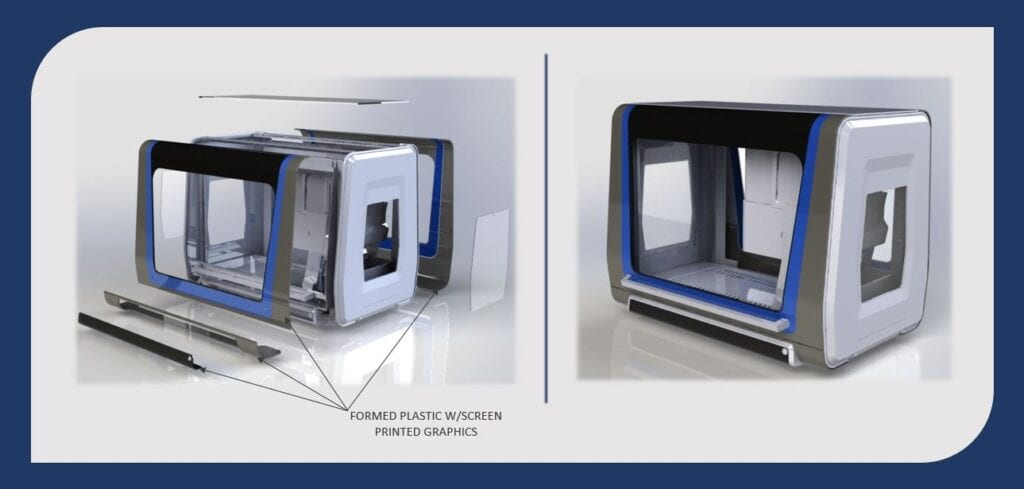

- Medical/Lab Equipment Enclosures. One of our primary offerings is medical and lab equipment enclosures. Aubright can work with medical companies to deliver equipment enclosure solutions for several applications. Whether our enclosures are used in hospitals, medical labs, or otherwise, we can work with customers from beginning to end to deliver quality solutions that benefit patients and medical staff. With our plastic fabrication capabilities, we provide customized enclosures that meet customer requirements for repeatability, tight tolerances, strength, and reliability.

- Food Service Displays. Our capabilities enable us to help manufacture many types of food service displays for caterers, hotels, bakeries, and other locations to showcase various food products.

- Construction/Agricultural Components. We offer a variety of products for the OEM agricultural sector, including cab components, dash components, and more.

When you turn to Aubright for custom OEM products, you’ll benefit from:

- Tolerances and Turnaround. Two of the main benefits you get with Aubright include tight tolerances and fast turnaround, which are both critical for many manufacturers.

- Reverse Engineering. Our engineering team can reverse-engineer your design to determine what your project specifically needs to be a success.

- Production Part Approval Process (PPAP). This procedure helps to ensure that manufacturers produce parts consistently. It entails multiple steps to maintain quality and efficiency while meeting the client’s expectations.

- Rapid Prototyping. This process involves testing designs and specifications to facilitate stability, reliability, and optimal performance. By manufacturing molds and tooling in-house, we reduce costs, enhance accuracy, and drive faster turnaround times for your project.

- In-house capabilities. By performing every aspect of your project under one roof, we can increase your speed to market while having greater control over quality and consistency.

Find High-Quality OEM Products at Aubright

When seeking the best OEM products for your application, consider turning to the experts at Aubright. We’ll help you successfully complete each project with consistent quality, efficiency, and cost-effectiveness using the most reliable equipment and materials.

To begin your next project with us, contact us online or call us at (320) 828-4035.